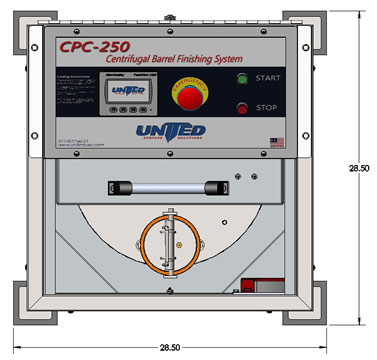

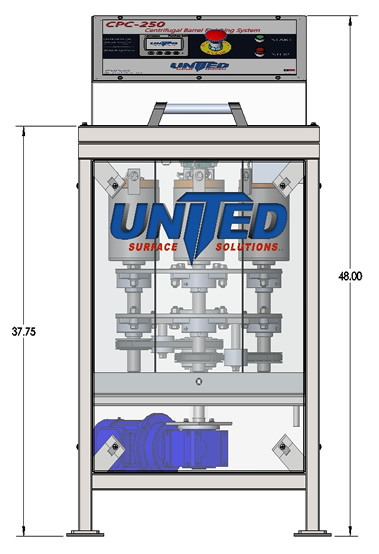

CPC250 Centrifugal Barrel

Small, Economical and Powerful - .25 CU FT

Unlike vibratory bowls, the CPC250 Centrifugal Barrel Finishing System yields quick and consistent results. Although it is smaller than other CBFs, it can deburr small parts 10 times faster than any vibratory tumbler with more consistency and precision. Deburring parts and separating them from tumbling media is also faster than vibratory deburring. With additional barrels on standby, parts and media can be changed in less than a minute. Due to its smaller barrels, the CPC250 consumes less media and compound than Mini Harperizers or other vertical barrel finishers.

STANDARD FEATURES

he CPC250 deburring machine is quiet enough to operate in an office environment. Ideal for deburring small parts and low volume production. Parts up to 5" x 4.5" can easily be processed in this unit. Smaller parts like dental components or screw components can be processed by the thousands.!

- Direct Drive system utilizes cleated belts which optimize performance and minimize noise and vibration. Removable panels make it simple to access all parts of the unit for maintenance.

- Touchscreen Controls with user friendly with process storage capabilities and process countdown timer.

- Safety Controls including two-handed jogging, E-Stop and interlocking access door.

- Variable Speed up to 350 RPM, is gentle on delicate parts and provides for process versatility.

- Removable Liners allows for fast loading and unloading and allows for quick liner replacement. An optional second set will allow operator to separate parts while the machine is processing another batch.

- Stainless Steel Construction for easy cleaning and durability..

- Removable Body Panels for ease of maintenance

- Cam Barrel Tops that allow for tool-free removal, resulting in less time to load or unload.

- WARRANTY: Up to 3 years based on component.

CPC250 Specifications

Free Sample Processing

We will process your parts at no cost to determine the best equipment and process for your application

Print our Sample Process Form to Submit your parts