TT...A/2C Series

THE DOUBLE BATCH PRINCIPLE

While one batch with finished parts is separated on the screening machine, a second batch is processed in the work bowl.

In this manner, costly idle times - especially for parts/media separation - can be minimized, thus achieving maximum productivity.

Double batch systems are ideally suites for Automation.

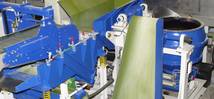

TANDEM MACHINES

The Tandem design- a version of the double batch principle - is suited for applications with relatively long processing times and short separation times: The Tandem machine is equipped with 2 work bowls, however with only one intermediate hopper and one screening machine. The combination of intermediate hopper/screening machine is alternately used from both work bowls.

Advantage: Saving space and costs!

TT...A/2C Series Specifications

Free Sample Processing

We will process your parts at no cost to determine the best equipment and process for your application

Print our Sample Process Form to Submit your parts